Table of Contents

- Introduction – The Machine That Changed the World

How the automobile became a global force of mobility, identity, and innovation. - A Brief History of the Automobile – From Horsepower to Horsepower

The evolution of cars from the Benz Patent-Motorwagen to electric supercars. - Under the Hood – The Science of Automotive Mechanics

How engines, transmissions, and chassis systems work in harmony to move us. - Auto Electronics – Where Software Meets Speed

From ECUs to ADAS, how digital systems transformed driving forever. - Car Manufacturing – Engineering Meets Mass Production

Inside the smart factories and robotic lines that build modern cars with scientific precision. - The Auto Industry – Economics on Wheels

Global trends, employment, and the geopolitical engine behind the automobile economy. - Innovation and Efficiency – Going Farther on Less

Engineering breakthroughs in weight, drag, and powertrain optimization. - Emissions and Environmental Impact – The Road to Sustainability

How the auto industry is tackling pollution, carbon, and the clean-energy transition. - The Future of Driving – Autonomy, Electrification, and Design Thinking

Where EVs, self-driving tech, and new mobility models are steering us next. - Conclusion – Reinventing the Ride

Why the automobile remains a symbol of progress—and how it must evolve.

1. Introduction – The Machine That Changed the World

Let’s be honest—nothing defines modern life quite like the automobile. From the rumble of a V8 on open asphalt to the whirr of an electric motor at a downtown stoplight, cars are more than transportation. They’re engineering, economy, expression, and evolution all rolled into one sleek, tire-clad package.

Since the late 19th century, the car has been the ultimate mobility machine—democratizing travel, shaping cities, fueling industries, and altering the literal course of civilization. There are now more than 1.4 billion cars on the road globally, with over 85 million motor vehicles produced each year across continents 【ACEA, 2024】. Whether it’s a handmade hypercar in Italy or a mass-produced EV rolling off a Chinese assembly line every 45 seconds, automobiles are the industrial heartbeat of the modern world.

But the magic of the car is far from simple. Beneath every hood is a symphony of science: internal combustion dynamics, gear ratios, fluid mechanics, electromagnetic signals, and lines of code. Cars are where physics, chemistry, materials science, electronics, and software engineering meet the everyday driver. And under the factory roof, it gets even wilder—robotic welders, AI-powered inspection cameras, and just-in-time logistics networks choreographing thousands of parts from hundreds of suppliers.

At the same time, the car faces a reckoning. Climate pressure, urban congestion, and changing consumer habits are forcing the industry to rethink what the car is—and what it should become. Plug-in hybrids, EVs, hydrogen fuel cells, and even solar-roofed prototypes are now not just fringe experiments but central to strategic roadmaps. And autonomy? It’s not science fiction—it’s in beta.

This article takes the long, winding, turbocharged road through where the car came from, how it works, who makes it, and where it’s headed next. Buckle up.

2. A Brief History of the Automobile – From Horsepower to Horsepower

If you think the modern car is fast, just look at how fast the idea of the car itself caught on. In just over 130 years, we’ve gone from the sputtering Benz Patent-Motorwagen (1886) to 2.0-liter turbocharged hybrids that can lap the Nürburgring faster than a racehorse can trot a mile.

The First Start: 1880s–1910s

The automobile’s story begins in Germany. Karl Benz’s three-wheeled gasoline-powered car is widely credited as the world’s first true automobile. Around the same time, in France and the U.S., engineers like Gottlieb Daimler, Emile Roger, and Charles and Frank Duryea were developing their own models—internal combustion was having its moment.

Then came Henry Ford. In 1908, the Model T changed everything. Not because it was the fastest or most beautiful—but because it was mass-producible. The moving assembly line, introduced in 1913, reduced production time per car from 12 hours to just 90 minutes. It also slashed costs, making car ownership a middle-class reality.

The Golden Age: 1920s–1960s

The roaring ’20s saw the automobile become a cultural icon. Road trips, diners, drive-ins—the whole American way of life revolved around the car. In Europe, marques like Citroën, Fiat, and Mercedes-Benz were pushing the envelope of style and engineering.

Post-World War II, automotive design exploded. Chrome flourishes, tailfins, and thundering V8s defined 1950s America. Meanwhile, Germany and Japan, rising from the ashes, began building what would become the most precise and durable cars in the world. Enter Toyota, Volkswagen, BMW, and Honda—brands that would later dominate the global market.

Muscle Meets Oil Crisis: 1970s–1980s

The ‘60s and early ‘70s were a paradise for horsepower junkies. The Mustang. The GTO. The Charger. But the 1973 oil crisis hit like a brick through a windshield. Gas prices soared, emissions regulations tightened, and suddenly efficiency mattered more than speed.

Japanese automakers responded with compact, fuel-efficient, and shockingly reliable vehicles—cars like the Toyota Corolla and Honda Civic reshaped the market. Meanwhile, Detroit scrambled to keep up, often producing bloated, underpowered “malaise era” cars that earned few fans.

The Tech Curve: 1990s–2000s

Fuel injection replaced carburetors. ABS became standard. Airbags proliferated. Onboard computers changed diagnostics forever. The ‘90s and early 2000s saw massive tech upgrades in drivetrains, emissions control, and comfort.

Cars became safer, more efficient, and smarter. Hybrid vehicles—led by the Toyota Prius (1997)—entered the mainstream, and manufacturers began tinkering seriously with electric platforms, even if range and price were still barriers.

Now: A Turning Point

Today, the car is at a crossroads. The internal combustion engine is no longer the undisputed king. Electric drivetrains, autonomy, and AI-assisted driving are reshaping what it means to “drive.” Tesla has become a household name. Ford’s Mustang now comes in EV form. And performance cars? They’re still alive—only now, they come with launch control, adaptive dampers, and silent acceleration.

The history of the automobile isn’t just about speed or tech—it’s about how we live, how we move, and how we imagine progress.

3. Under the Hood – The Science of Automotive Mechanics

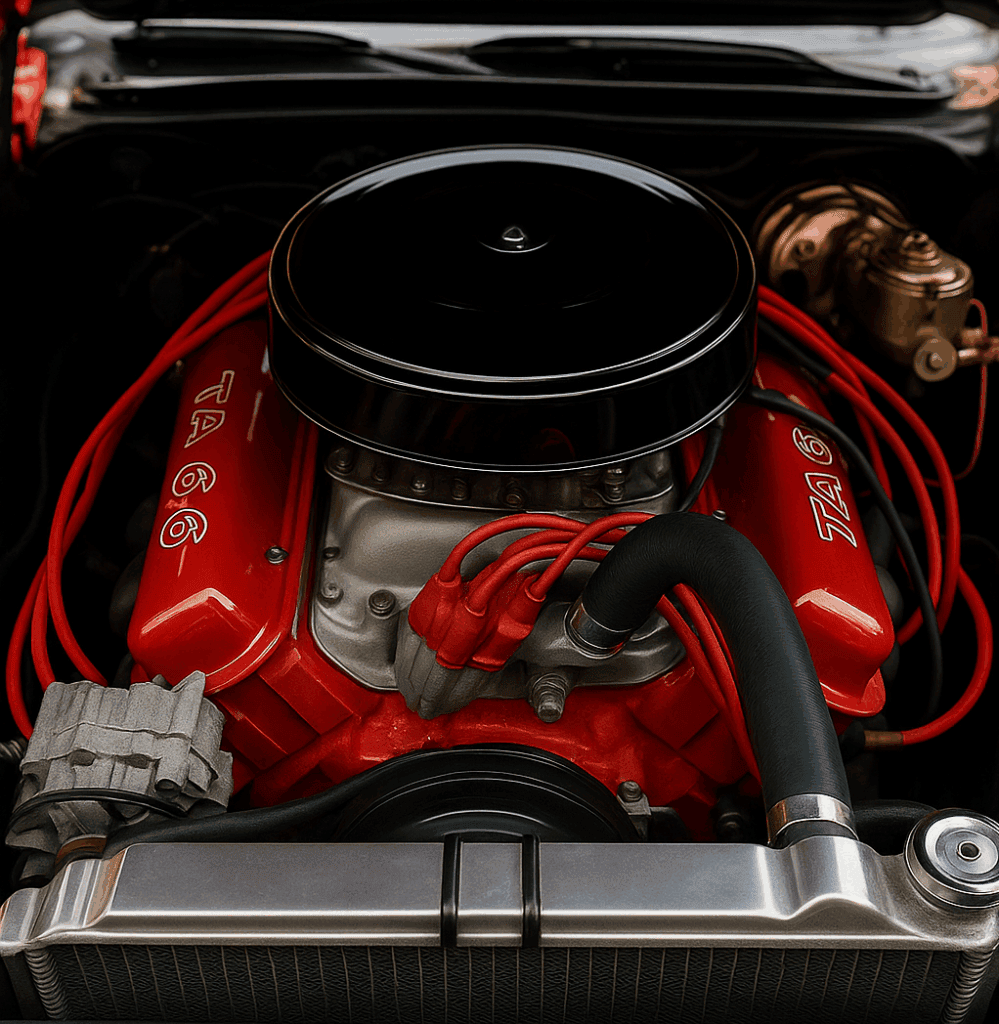

Pop the hood on any car—classic V8, turbocharged inline-4, or hybrid powertrain—and you’ll find a world where thermodynamics, fluid mechanics, and mechanical engineering converge in a symphony of controlled explosions and frictionless motion. Cars don’t just run—they perform, and it’s science that makes the performance possible.

The Internal Combustion Engine: Power from Fire

At its core, a gasoline engine is a heat-to-motion converter. Air and fuel enter a cylinder, mix, compress, and ignite—usually thanks to a spark plug—creating a controlled explosion that drives a piston. The piston’s motion turns the crankshaft, which eventually spins your wheels.

We call this the Otto Cycle, a four-stroke process:

- Intake (air-fuel mixture enters),

- Compression (the piston rises),

- Power (ignition pushes the piston down),

- Exhaust (burned gases exit).

Each part of this cycle depends on precision engineering: combustion chamber shape, valve timing, compression ratios, and even the swirl of air entering the cylinder.

Turbochargers and superchargers boost performance by forcing more air in, increasing power without increasing displacement. Meanwhile, direct injection and variable valve timing improve fuel efficiency and throttle response.

Transmissions: Managing Torque and Speed

Engines spin best at high RPMs; wheels need lower RPMs. That mismatch is solved by the transmission, which adjusts gear ratios to optimize speed and power delivery.

- Manual transmissions give the driver direct control via clutch and gear stick.

- Automatics use torque converters and planetary gears to shift smoothly.

- CVTs (Continuously Variable Transmissions) offer infinite gear ratios for maximum efficiency, often found in hybrids and small cars.

The transmission system is a field of mechanical logic and design—fluid couplings, gear ratios, shifting maps—all engineered to translate engine output into seamless motion.

Suspension, Steering, and Brakes: Control Systems in Motion

A good car doesn’t just go fast—it handles, corners, and stops with confidence. That’s the job of the suspension, steering, and braking systems.

- Suspension systems (MacPherson struts, double wishbones, adaptive dampers) manage comfort, traction, and body control.

- Steering systems (rack and pinion, electric power steering) provide precision and feedback.

- Brakes (disc, drum, ABS, regenerative systems in EVs) convert kinetic energy into heat or electrical charge.

Here, Newtonian physics rules. You’re balancing forces—lateral grip, inertia, and weight transfer. Engineering firms use simulation software and wind tunnels to fine-tune every bushing and arm to optimize cornering feel and stability.

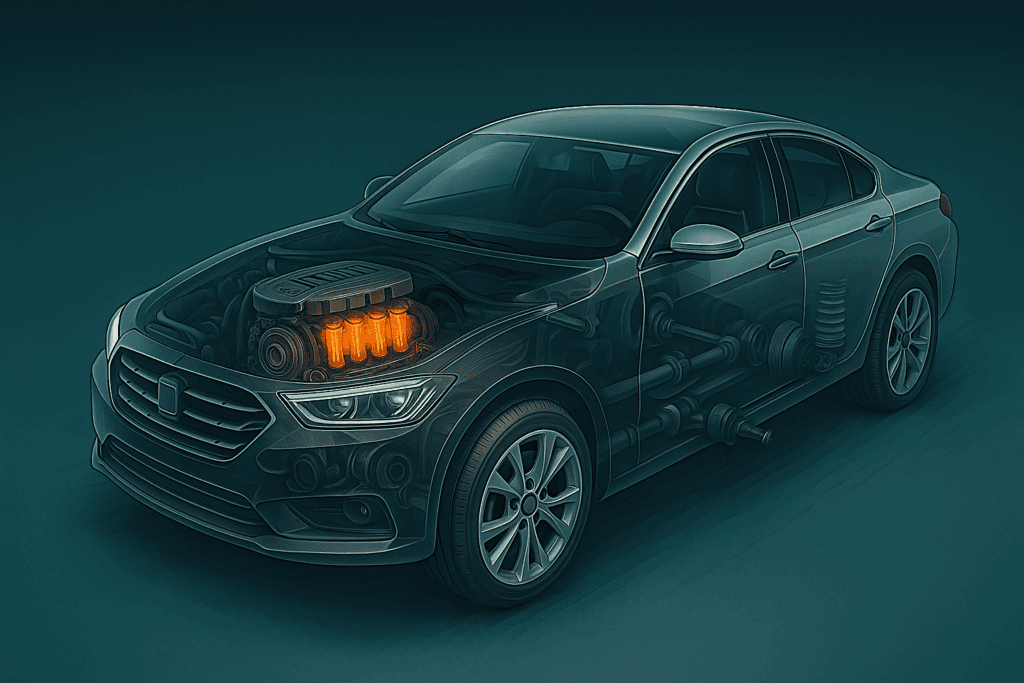

Chassis and Drivetrain Layouts

The layout of a car—engine position and which wheels are driven—defines its handling character:

- FWD (Front-Wheel Drive): Efficient and simple, common in compacts

- RWD (Rear-Wheel Drive): Better balance and sporty dynamics

- AWD/4WD: Enhanced traction for performance or off-roading

- Mid-Engine: High-performance layout for balance and responsiveness

Each layout comes with trade-offs in packaging, weight distribution, and traction. It’s mechanical architecture with purpose.

In every rev and every curve, there’s science at work. And the deeper you go under the hood, the more you realize: a car isn’t just metal—it’s precision motion, choreographed by physics and forged in fire.

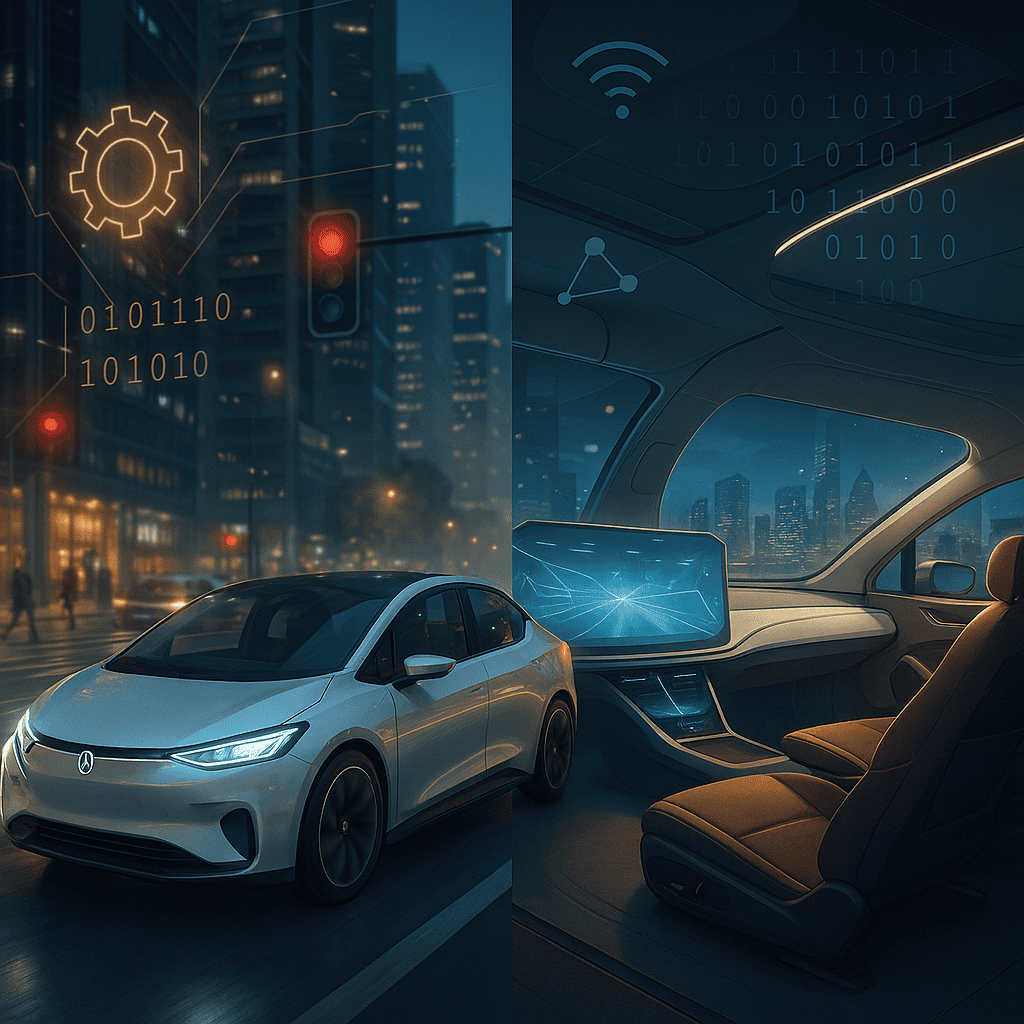

4. Auto Electronics – Where Software Meets Speed

The modern car is less like a carriage and more like a rolling computer. Beneath the body panels and behind the dash lies an intricate web of wires, sensors, processors, and code. Electronics no longer just assist—they dominate everything from safety to steering, from climate to cruise control.

The Car’s Nervous System: ECUs and Sensors

Modern vehicles rely on ECUs (Electronic Control Units)—tiny computers responsible for specific functions. Most cars today have between 50 and 100 ECUs, coordinating systems like fuel injection, airbag deployment, infotainment, and braking.

These ECUs process data from hundreds of sensors:

- Oxygen sensors measure emissions and fuel mix

- Wheel speed sensors feed anti-lock braking and traction control

- Gyroscopes and accelerometers stabilize motion in dynamic handling systems

- Proximity sensors and cameras enable parking assist and collision warnings

In total, the average car now generates 25 gigabytes of data per hour, and that number is climbing.

From Gauges to Screens: Infotainment and UX

Forget the AM radio. Today’s dashboards feature digital clusters, touchscreens, and head-up displays (HUDs). Car interfaces now blend UX design, AI-driven voice assistants, and real-time connectivity.

Navigation is GPS-based and traffic-aware. Your car might even sync with your phone, your calendar, or your Spotify queue before you sit down. Systems like Apple CarPlay, Android Auto, and in-car Wi-Fi are becoming standard even in base trims.

Advanced Driver Assistance Systems (ADAS)

ADAS is where electronics meet real-time road awareness. These systems assist the driver in making safer decisions and, increasingly, take over certain driving tasks.

Common ADAS features include:

- Adaptive cruise control

- Lane keeping assist

- Automatic emergency braking (AEB)

- Blind-spot monitoring

- Pedestrian detection

These technologies use a fusion of radar, lidar, sonar, and cameras, analyzed via high-speed processors with machine learning capabilities.

While most cars today fall under Level 1 or 2 autonomy, we’re entering Level 3 territory, where the car handles all tasks in certain conditions (see: Mercedes-Benz Drive Pilot or Tesla FSD Beta).

V2V, V2X, and OTA – The Connected Future

Vehicle-to-vehicle (V2V) and vehicle-to-everything (V2X) communication are turning cars into networked machines, able to warn one another about hazards, sync with traffic infrastructure, and optimize traffic flow.

Meanwhile, over-the-air (OTA) updates—pioneered by Tesla—let cars receive new features, bug fixes, and performance tweaks wirelessly. Your car evolves after you buy it.

Cybersecurity and Ethics

With all this connectivity comes risk. Cars can be hacked. Data can be stolen. Engineers now work on automotive cybersecurity, encryption protocols, and fail-safe systems to ensure that smart cars remain safe cars.

The engine may move the car, but electronics direct the dance—and increasingly, they’re writing the music. From throttle response to lane centering, the science of automotive electronics is shaping the next generation of driving—sometimes, without a driver at all.

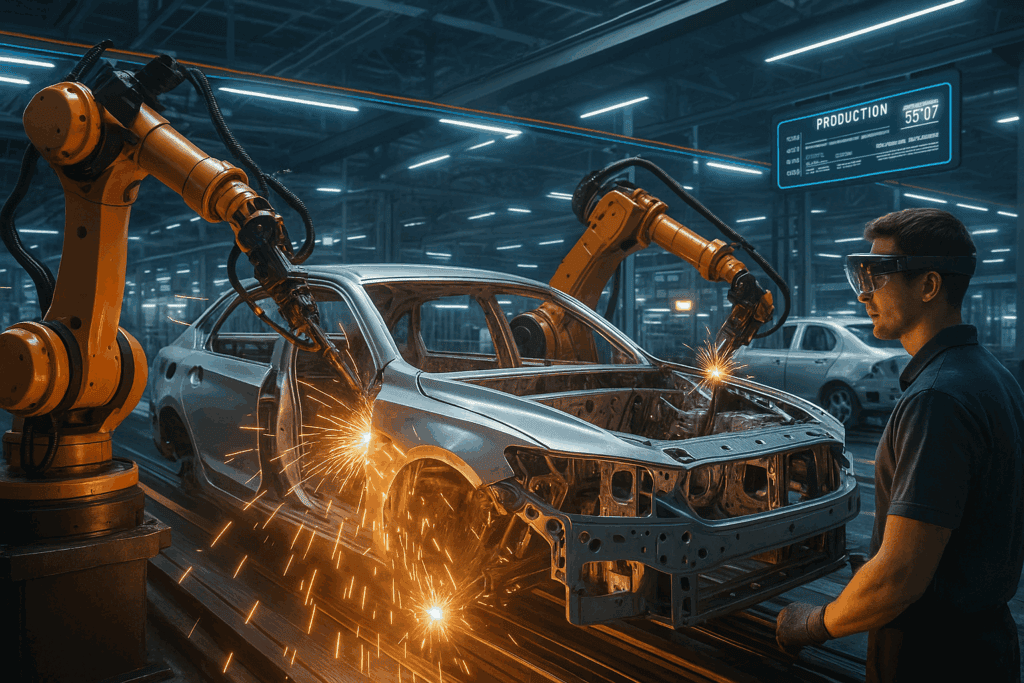

5. Car Manufacturing – Engineering Meets Mass Production

Making a car isn’t just about assembling metal and rubber—it’s one of the most complex feats of engineering on Earth. A modern vehicle is the product of thousands of precision components, sourced globally, built on robotic assembly lines, and inspected by AI-powered systems that spot imperfections invisible to the human eye. Every car is a machine built by machines, guided by data, logistics, and lean design.

From Raw Material to Rolling Art

Manufacturing begins long before the factory floor. Aluminum, steel, plastic, glass, and composites are sourced, processed, and molded using techniques honed over a century. Panels are stamped into shape with thousands of pounds of pressure. Frames are welded by robotic arms executing movements down to fractions of a millimeter.

- Body-in-white assembly brings together the raw frame

- Paint shops use electrostatic attraction and climate control to deliver flawless finishes

- Powertrains are built separately, tested, then integrated in final assembly

- Interior trim, electronics, and final inspection follow

A single car can contain 30,000+ parts, many of which come from hundreds of suppliers across continents. Just-in-time delivery systems, first perfected by Toyota, minimize warehousing and maximize flow—though they also reveal fragility, as seen in recent semiconductor shortages.

Robotics and Automation

Modern car plants are showcases for industrial automation. Robots do the heavy lifting, welding, gluing, riveting, and even some painting. According to AutoClub data, up to 90% of manufacturing tasks in some plants are robotic, especially in chassis and body construction.

AI-enhanced vision systems inspect welds, measure gaps, and identify defects. Machine learning algorithms optimize production sequences and predict maintenance needs before breakdowns occur. In premium plants, even quality control is assisted by autonomous rolling bots.

Digital Twins and Smart Factories

Manufacturers increasingly use digital twins—virtual models of the physical car and its production line—to simulate, test, and refine before building anything in reality. These smart factories allow:

- Real-time monitoring of energy and emissions

- Rapid retooling for new models

- Continuous optimization through IoT data feedback

The science of manufacturing is no longer just mechanical—it’s now deeply computational.

Global Production Footprint

According to ACEA, in 2023:

- China produced over 26 million vehicles (nearly a third of the global total)

- Europe manufactured around 13 million

- North America added 11 million

- The global total exceeded 85 million vehicles

With production spread across regions, automakers design platforms that can be built in multiple locations, with local variations for market, safety, and emissions standards.

Sustainability and Circular Manufacturing

Modern plants are increasingly focused on sustainability:

- BMW’s Leipzig plant runs partially on wind power

- Toyota’s “zero landfill” strategy recycles nearly all waste

- Ford and GM are incorporating closed-loop aluminum and battery recycling

Lifecycle assessment now includes not just what a car emits on the road, but how it was made—and how its materials will be reused at the end of life.

Building a car today means orchestrating robots, engineers, AI systems, and global supply chains with surgical precision. It’s not just manufacturing—it’s a full-spectrum science of motion, material, and modernity.

6. The Auto Industry – Economics on Wheels

Cars aren’t just machines—they’re a global economic engine. The automotive industry is one of the largest and most influential sectors in the world, directly employing over 9.6 million people globally, with millions more in supply chains, dealerships, logistics, and fuel infrastructure 【CAR.org】. From steel mills to silicon foundries, few sectors ripple as widely across the economy.

The Big Players: Global Reach, Local Impact

The world’s top automakers operate like sovereign entities, with sprawling international footprints. The leaders in global vehicle production and brand influence include:

- Toyota (Japan) – known for quality, hybrid leadership, and lean manufacturing

- Volkswagen Group (Germany) – encompassing VW, Audi, Porsche, and more

- Hyundai–Kia (South Korea) – global growth champions with competitive tech

- General Motors, Ford, and Stellantis (USA) – legacy giants with deep EV pivots

Manufacturers often operate regional platforms, meaning the same basic vehicle architecture may underpin multiple brands or models tailored for different markets.

Production, Sales, and Market Shifts

According to 2023 data from ACEA:

- Over 85 million vehicles were produced globally

- Asia-Pacific remains the dominant region, led by China’s vast domestic demand

- Europe and North America continue as design and export powerhouses

- Emerging markets in India, Southeast Asia, and Africa are seeing rapid growth

Sales trends show:

- SUVs and crossovers dominate nearly every major market

- Sedans and hatchbacks are declining, though still key in Europe and Asia

- Electric vehicles (EVs) now account for 10–15% of global sales and rising fast

Industry Economics: Scale, Speed, and Strategy

The automotive business depends on volume and scale. Margins are razor-thin, and a factory shut down by one missing chip can cost millions per day. That’s why:

- Platform sharing (e.g., VW’s MQB, Toyota’s TNGA) is essential

- Outsourcing non-core systems (e.g., infotainment, sensors) reduces costs

- Global supply chain management is treated as a science in itself

Manufacturers invest billions in R&D (Tesla spent $3.5B in 2022 alone), not just in engineering, but also in market forecasting, user data, and software ecosystems.

Jobs and Transformation

The industry is undergoing a workforce transformation:

- Internal combustion specialists are retraining for EV platforms

- Battery manufacturing and recycling are booming sub-industries

- Tech-sector talent (AI, software, UX) is now in demand at car companies

Governments and unions are grappling with how to transition jobs responsibly. The shift to EVs may eliminate many traditional roles—while creating new ones in clean tech and digital systems.

Global Challenges: Chips, Tariffs, and Tensions

- The semiconductor shortage exposed how deeply cars now rely on digital components—many vehicles need over 1,500 chips

- Trade tensions (e.g., US-China, EU tariffs) impact supply chain stability

- Climate regulations in Europe, the U.S., and China are forcing strategic shifts at an unprecedented pace

The auto industry is no longer just about horsepower—it’s about policy, production, powertrains, and planet. In this ecosystem, one design decision in Tokyo might ripple to a parts supplier in Mexico, an EV battery mine in Chile, and a customer in Norway.

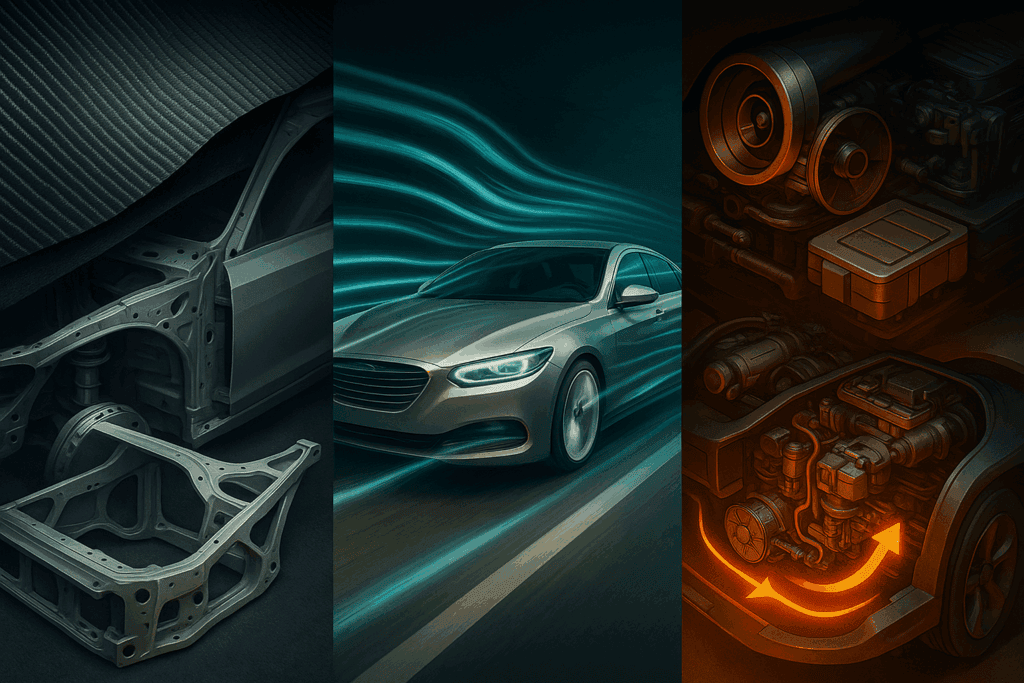

7. Innovation and Efficiency – Going Farther on Less

In the relentless pursuit of speed, comfort, and sustainability, the automotive industry has become a laboratory for innovation. Every gram shaved, every joule saved, and every drop of fuel squeezed more efficiently out of an engine is the result of decades of scientific advancement. The goal? Make cars that go farther, faster, cleaner—and smarter.

Lightweighting: Shedding Pounds to Gain Performance

Mass is the enemy of efficiency. The lighter the car, the less energy required to move it. That’s why automakers use:

- High-strength steel for structural safety with reduced thickness

- Aluminum (used extensively in Audi and Jaguar Land Rover) for body panels and frames

- Carbon fiber in high-performance and luxury vehicles for extreme weight savings

- Plastics and composites in everything from dashboards to underbody panels

Even gram-level decisions matter. BMW’s i3 cut weight with carbon-fiber reinforced plastic (CFRP), while Mazda’s SkyActiv platform redesign focused on “gram strategies” across the whole chassis.

Aerodynamics: Slip Through the Wind

Every car battles wind resistance. The more streamlined the body, the less energy needed to maintain speed. Engineers use:

- Wind tunnels and CFD (computational fluid dynamics) modeling

- Features like active grille shutters, underbody smoothing, and drag-reducing wheel designs

- A growing focus on lift reduction for high-speed stability and EV range

Modern sedans like the Mercedes EQS achieve a drag coefficient (Cd) as low as 0.20—better than most raindrops.

Engine Optimization: Smaller, Smarter, Stronger

Internal combustion is far from dead—it’s just getting smarter.

- Turbocharging allows smaller engines to deliver more power with better fuel economy

- Direct injection maximizes combustion efficiency

- Variable valve timing and cylinder deactivation adjust performance on demand

- Mild hybrids (48V systems) add low-speed torque and reduce engine load

The result? A 1.5L three-cylinder engine today can outperform a 2.5L engine from a decade ago, and use less fuel doing it.

Start-Stop and Smart Energy Management

Start-stop systems shut off the engine at idle, reducing unnecessary burn. Energy recovery systems—especially in hybrids—capture kinetic energy during braking and deceleration to power onboard electronics or recharge batteries.

This reduces fuel consumption in city driving by up to 10–15%—a meaningful figure in today’s emissions-conscious world.

Tires, Lubricants, and Hidden Gains

Even low rolling resistance tires and low-friction engine oils can bump fuel efficiency by several percentage points. These incremental innovations—often overlooked—accumulate into major savings across millions of cars.

In short, innovation isn’t just happening in flashy EV startups. It’s baked into every bolt and panel. Whether it’s nanocoatings that reduce friction or AI models that simulate airflow, the science of efficiency is now a core pillar of vehicle design.

8. Emissions and Environmental Impact – The Road to Sustainability

Let’s be blunt: cars have a pollution problem. The internal combustion engine (ICE), for all its brilliance, burns fossil fuels—and that means carbon dioxide (CO₂), nitrogen oxides (NOx), particulates, and other byproducts that harm both planet and people. But the auto industry isn’t idling. From emissions-scrubbing tech to a full EV pivot, manufacturers are rewriting what it means to go green.

What Cars Emit

A typical gasoline car emits:

- CO₂ – the main greenhouse gas driving climate change

- NOx – contributes to smog and respiratory illness

- PM2.5 and PM10 – tiny particulates harmful to lungs

- Unburned hydrocarbons – react in sunlight to form ground-level ozone

According to the U.S. EPA, transportation accounts for about 29% of greenhouse gas emissions in the U.S., more than any other sector. Globally, it’s around 15–20% and rising with increased vehicle use.

Tech That Cleans Up Combustion

To keep ICEs compliant with tightening standards, automakers use:

- Catalytic converters – convert CO, NOx, and hydrocarbons into less harmful gases

- Gasoline particulate filters (GPFs) – trap soot particles

- Exhaust gas recirculation (EGR) – reduces NOx formation by lowering combustion temps

- Selective catalytic reduction (SCR) – diesel exhaust is treated with urea (AdBlue) to neutralize NOx

Modern ICE vehicles emit far less than those from the 1990s—but with over a billion cars on the road, even a little adds up.

The EV Advantage—and Its Caveats

Electric vehicles (EVs) produce zero tailpipe emissions, a huge plus for urban air quality. They also help lower total emissions in countries with clean electricity grids.

But EVs aren’t pollution-free:

- Battery production is energy- and resource-intensive, involving materials like lithium, cobalt, and nickel

- Electricity sources vary—coal-heavy grids dilute EV benefits

- End-of-life recycling is still catching up, especially for lithium-ion cells

Lifecycle studies generally show EVs have 30–60% lower total emissions over their lifespan compared to gasoline cars, improving as grids go greener.

Hybrid and Alternative Solutions

- Hybrids and plug-in hybrids (PHEVs) bridge the gap, reducing fuel use without full electrification

- Hydrogen fuel cell vehicles (FCEVs) emit only water vapor and refuel in minutes, though infrastructure is scarce

- Synthetic e-fuels—carbon-neutral fuels created from captured CO₂ and green hydrogen—may offer a future for ICE tech without the carbon penalty

Global Emissions Standards and Industry Response

Governments are tightening the screws:

- The EU will ban the sale of new ICE cars by 2035

- California follows suit with a phased ban starting 2035

- China, the world’s biggest market, is rapidly expanding EV subsidies and mandates

Manufacturers are responding:

- Volvo promises to go fully electric by 2030

- GM plans to end ICE production by 2035

- Toyota, BMW, and others pursue multi-path strategies: EV, hybrid, hydrogen

The road to sustainability is long—but the auto industry is no longer just trying to outrun emissions. It’s racing to engineer them out of existence. The goal isn’t just zero to 60—it’s zero emissions, full stop.

9. The Future of Driving – Autonomy, Electrification, and Design Thinking

The automotive industry isn’t just evolving—it’s reinventing the very idea of what a car is. As electrification meets automation and digital design, tomorrow’s vehicle will look less like a descendant of the Model T and more like a fusion of smartphone, living room, and robotic assistant. We’re not just driving toward the future—we’re riding into it.

Electrification Goes Mainstream

EVs aren’t fringe anymore—they’re the growth segment.

- Tesla remains the face of electric disruption, delivering over 1.8 million vehicles in 2023 alone

- Legacy giants like Ford (F-150 Lightning), GM (Ultium platform), and Volkswagen (ID series) are betting billions on EV lineups

- China’s BYD, NIO, and XPeng are setting new benchmarks for affordable innovation

Battery tech is the beating heart of EV progress. New chemistries like lithium iron phosphate (LFP) and solid-state batteries promise higher range, faster charging, and greater safety.

Fast-charging networks are also growing:

- Tesla Supercharger (now open to non-Tesla EVs in many markets)

- Electrify America, Fastned, Ionity, Shell Recharge—building out Europe and North America

- Smart grids and vehicle-to-grid (V2G) tech could let your EV power your home—or the neighborhood

Autonomous Driving: Hype Meets Hardware

Self-driving cars were once sci-fi. Now? They’re in beta.

- Level 2 (driver assist) is standard in many new cars: lane centering, adaptive cruise, auto-brake

- Level 3 (hands-off, eyes-off in specific conditions) is rolling out in cars like the Mercedes-Benz EQS with Drive Pilot

- Waymo, Cruise, and Motional are running Level 4 robo-taxis in controlled U.S. cities

Full autonomy (Level 5) is still years out—complex edge cases, weather, infrastructure, and liability remain barriers. But the tech is improving rapidly, powered by:

- LIDAR, radar, and HD mapping

- Neural networks and real-time object classification

- Massive edge computing power inside the vehicle

Design Thinking and Software-Defined Vehicles

In tomorrow’s car, hardware won’t define the experience—software will.

- Interiors will become more like lounges: minimalist dashboards, reclining seats, mood lighting, voice control

- Augmented reality HUDs, 360° cabin sensors, and gesture control will replace buttons and knobs

- OTA (over-the-air) updates will keep the car improving for years—just like your phone

Software-defined vehicles (SDVs) are modular platforms with centralized computing. This means faster development cycles, feature unlocks via subscription, and continuous personalization.

Mobility as a Service (MaaS) and Changing Ownership

Fewer young people want to own cars. In cities, services like Uber, Lyft, Zipcar, and micro-mobility fleets (e-bikes, scooters) are taking over.

Automakers are adapting:

- Car subscriptions (Polestar, Volvo) offer flexibility over ownership

- Fleet sales are rising as companies bet on shared mobility

- In-car commerce and advertising are emerging revenue streams

Design for a Climate-Conscious Future

Future vehicles will be judged not just on horsepower or handling, but on emissions, recyclability, and social impact. Circular economy principles are emerging:

- Recycled materials in interiors (e.g. ocean plastics, vegan leather)

- Battery second-life uses (home power storage)

- Cradle-to-cradle design focused on easy disassembly and reuse

The car of tomorrow won’t just drive—it’ll listen, learn, self-improve, and serve as your mobile assistant. What we’re witnessing isn’t just a technological transition—it’s a paradigm shift in how we move, think, and live.

10. Conclusion – Reinventing the Ride

For over a century, the automobile has been more than a mode of transport—it’s been a cultural force, an economic engine, and a rolling canvas of science, design, and ambition. From steam-breathing beasts to silent electric rockets, from chrome-draped cruisers to code-powered pods, cars have never stopped evolving. And neither have we.

We’ve taken a ride through combustion chemistry, torque management, aerodynamic drag, digital dashboards, and global economics. We’ve seen how the automotive world runs on steel and software, on labor and lasers, on history and hope. At every stage—whether it was building a better crankshaft or decoding sensor fusion for autonomous driving—science has driven the car forward.

But now, the road ahead is more uncertain—and more exciting—than ever. The stakes are higher. The questions are bigger. Can we decarbonize a trillion-dollar industry? Can we build transportation that’s equitable, efficient, and ethical? Can we replace speed and power with sustainability and purpose?

The answer, as always, lies in engineering, imagination, and the relentless drive to go farther—not just across highways, but into new realms of design, ecology, and possibility.

So whether you’re wrenching in a garage, coding ADAS software, designing lightweight alloys, or just cruising with the windows down, know this:

The car is not a relic—it’s a revolution still in motion.